The newly developed die spraying machine ESM (Efficient Spray Machine) offers,together with the also new machine control PC3, complete Industry 4.0 integration.

The ESM series is the future-oriented further development of the previous PSM spraying machines and is available as linear spraying machines ESM 2 – 4.

ESM die spraying machines are characterized by significant advantages:

- Increase in payload with no increase in space requirements

- Easier integration of fl ow measuring, pressure monitoring and pressure control, EcoSpray ect.

- Higher integration density – more cost-effective options

- Exchange compatible to predecessor series

- Spraying tool adaption compatible to predecessor series

- Easier maintenance

- New concept for air- and Lubricant lines

- Optional predictive maintenance – industry 4.0

- Operation through the die casting machine or by using a tablet or mobile phone

Linear Spraying Machine ESM2

| DGM range (kN) | 1.600 – 10.000 |

| Drive system | AC-Servo |

| Vertical stroke (mm) | 800/1000/1300 |

| Horizontal stroke (mm) | 800/1000/1200/ Assembly stand |

| Controllers | PC3 |

| Spraying circles single & combined, can be switched on & off |

4 spraying circuits |

| Afterblowing circuits single & combined, can be switched on & off |

4 afterblowing circuits |

| High-pressure | 2 high-pressure blowing circuits |

| Compressed air connection | 2 x 1“ on ESM 1 x 2“ at pressure control / air connection set |

| Separating agent connection | 1/2“ for mixture 3/8“ for concentrate |

| Separating agent supply | 2 – 8 bar |

| Spray & afterblow air | 2 – 8 bar |

| High-pressure blow circuit | 4 – 8 bar |

| Air throughput | 700 Nm³/h |

| Spraying head weight | 45 kg |

| Acceleration vertical & horizontal axis |

2m/s² |

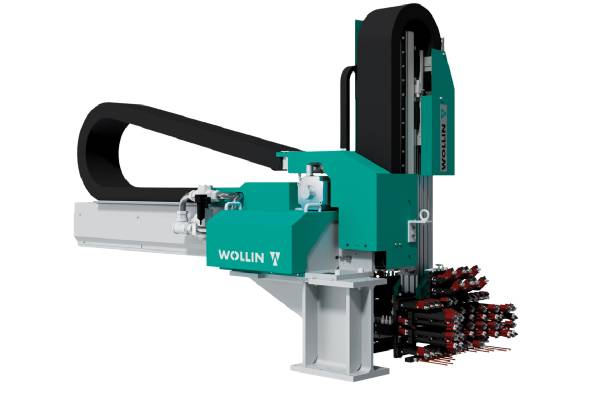

Linear Spraying Machine ESM3

| DGM range (kN) | 5.600 – 20.000 |

| Drive system | AC-Servo |

| Vertical stroke (mm) | 1300/1600/2000 |

| Horizontal stroke (mm) | 1000/1200/1600/2000 |

| Controllers | PC3/PC84 |

| Spraying circles single & combined, can be switched on & off |

6 spraying circuits |

| Afterblowing circuits single & combined, can be switched on & off |

6 afterblowing circuits |

| High-pressure | 2 high-pressure blowing circuits |

| Compressed air connection | 2 x 1,5“ on ESM 1 x 2“ at pressure control / air connection set |

| Separating agent connection | 1“ for mixture 3/8“ for concentrate |

| Separating agent supply | 2 – 8 bar |

| Spray & afterblow air | 2 – 8 bar |

| High-pressure blow circuit | 4 – 8 bar |

| Air throughput | 2000 Nm³/h |

| Spraying head weight | 100 kg |

| Acceleration vertical & horizontal axis |

2m/s² |

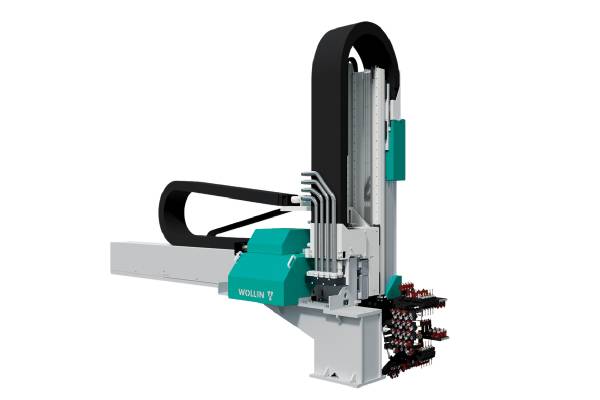

Linear Spraying Machine ESMT3

| DGM range (kN) | 5.600 – 20.000 |

| Drive system | AC-Servo |

| Vertical stroke (mm) | 1300/1600/2000 (telescope) |

| Horizontal stroke (mm) | 1000/1200/1600/2000 |

| Controllers | PC3/PC84 |

| Spraying circles single & combined, can be switched on & off |

6 spraying circuits |

| Afterblowing circuits single & combined, can be switched on & off |

6 afterblowing circuits |

| High-pressure | 2 high-pressure blowing circuits |

| Compressed air connection | 2 x 1,5“ on ESM 1 x 2“ at pressure control / air connection set |

| Separating agent connection | 1“ for mixture 3/8“ for concentrate |

| Separating agent supply | 2 – 8 bar |

| Spray & afterblow air | 2 – 8 bar |

| High-pressure blow circuit | 4 – 8 bar |

| Air throughput | 2000 Nm³/h |

| Spraying head weight | 130 kg |

| Acceleration vertical & horizontal axis |

2m/s² |

Linear Spraying Machine ESM4

| DGM range (kN) | 20.000 – 62.000 |

| Drive system | AC-Servo |

| Vertical stroke (mm) | 2000/2500 |

| Horizontal stroke (mm) | 2000/2500 |

| Controllers | PC3/PC84 |

| Spraying circles single & combined, can be switched on & off |

8 spraying circuits |

| Afterblowing circuits single & combined, can be switched on & off |

8 afterblowing circuits |

| High-pressure | 2 high-pressure blowing circuits |

| Compressed air connection | 2 x 1,5“ on ESM 1 x 2“ at pressure control / air connection set |

| Separating agent connection | 1“ for mixture 3/8“ for concentrate |

| Separating agent supply | 2 – 8 bar |

| Spray & afterblow air | 4 – 8 bar |

| High-pressure blow circuit | 4 – 8 bar |

| Air throughput | 2500 Nm³/h |

| Spraying head weight | 200 kg |

| Acceleration vertical & horizontal axis |

2m/s² |

Linear Spraying Machine ESMT4

| DGM range (kN) | 20.000 – 62.000 |

| Drive system | AC-Servo |

| Vertical stroke (mm) | 2200/2800 (telescope) |

| Horizontal stroke (mm) | 2000/2500 |

| Controllers | PC3/PC84 |

| Spraying circles single & combined, can be switched on & off |

8 spraying circuits |

| Afterblowing circuits single & combined, can be switched on & off |

8 afterblowing circuits |

| High-pressure | 2 high-pressure blowing circuits |

| Compressed air connection | 2 x 1,5“ an ESM 1 x 2“ at pressure control / air connection set |

| Separating agent connection | 1“ for mixture 3/8“ for concentrate |

| Separating agent supply | 2 – 8 bar |

| Spray & afterblow air | 4 – 8 bar |

| High-pressure blow circuit | 4 – 8 bar |

| Air throughput | 2500 Nm³/h |

| Spraying head weight | 280 kg |

| Acceleration vertical & horizontal axis |

2m/s² |

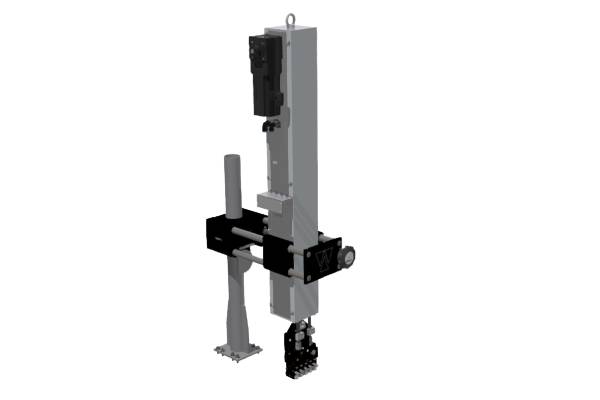

Linear Spraying Machine ESM1 LC

| DGM range (kN) | 800 |

| Drive system | Timing belt |

| Vertical stroke (mm) | 600 – 800 |

| Horizontal stroke (mm) | – |

| Controllers | SC2 (S71500-Siemens) |

| Spraying circles single & combined, can be switched on & off |

2 spraying circuits |

| Acceleration | 2,75m/s² |

| Interface | DISPO25 |