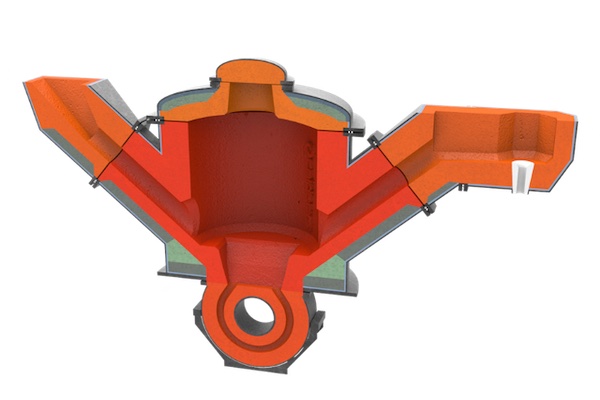

FOR PROFITABLE, HIGH QUALITY CASTINGS IN GREY IRON FOUNDRIES

|

MORE EFFICIENCY WITH THE

|

UPGRADE TO AUTOMATION

Each of our products is designed to be equipped with software, lasers and cameras on request. Upgrade the system to speed up pouring process and work steps to a large extent with less effort at the same time. When talking about automatic pouring, we distinguish between three levels that build on one another.

The unheated stopper pouring ladle can be easily upgraded at any time in order to start with a simple manual system and convert it to a sophisticated, automated system. By adding special features, it may be possible to significantly increase the production output while reducing the manpower to do it.

|

|

|

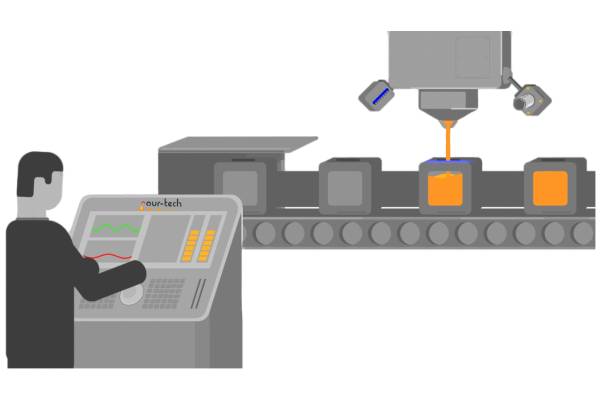

| SEMI-AUTOMATIC POURING A solid and constant pouring process for your production. |

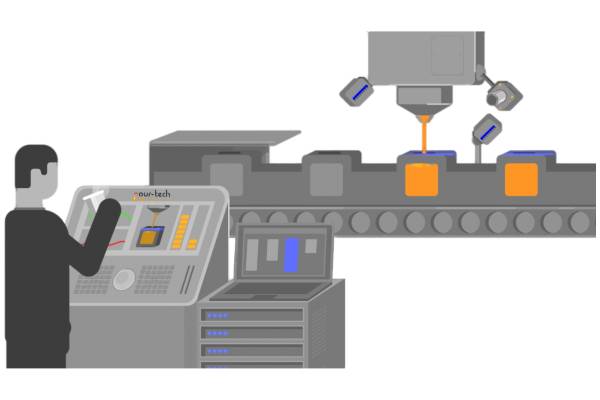

AUTOMATIC POURING Pouring upgrade leading to a fast, independent and accurate process. |

INTELLIGENT POURING The high-end solution for an intelligent and a self-learning production. |